Glass industry is an energy-intensive industry, the traditional production methods of energy consumption, pollutant emissions. Under the national "double carbon" strategy, green manufacturing has become a necessary path for the sustainable development of the glass industry. Qinhuangdao Aohua Glass Co., Ltd. has taken green manufacturing as its core concept since the beginning of its establishment, and actively laid out energy-saving and emission reduction technology, clean energy application and intelligent manufacturing system, forming a low-carbon, high-efficiency, intelligent and environmentally friendly industry development paradigm.

I. Integration of environmental protection concepts into the whole project cycle

Located in the Circular Economy Industrial Park of Changli Economic Development Zone, Aohua's project has prioritized environmental protection elements since its site selection. Its float production line not only has high capacity, but also is equipped with dry desulfurization, ceramic filter tube denitrification dust removal system, particulate matter, sulfur dioxide, nitrogen oxides emissions are far below the national standards.

The company was honored with the title of "A-class enterprise of environmental protection performance in key industries", which proves that the maturity and execution of its environmental protection system is at the leading level in the industry.

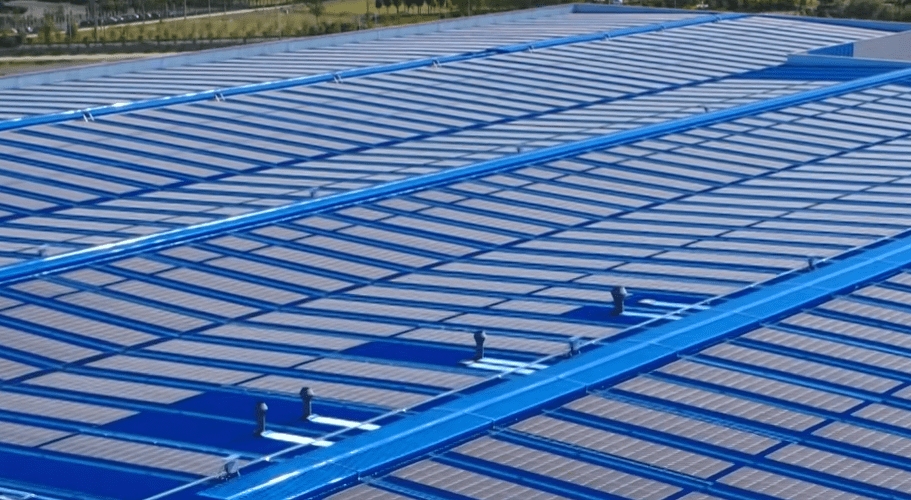

II. Clean energy system to build a green factory

About 80,000 square meters of photovoltaic modules are laid on the roof of Aohua's plant, with a total installed capacity of 10MW, generating 12 million kWh of electricity annually, effectively compensating for the need for production electricity. Combined with the flue gas waste heat power generation system, the annual energy saving and carbon reduction effect is remarkable. At the same time, the enterprise has also established an energy management system (ISO50001), which realizes the optimal energy consumption of the production process by monitoring the energy consumption structure and energy saving performance indicators.

The successful implementation of this model, not only for their own economic and brand benefits, but also for the industry to explore the path of green factories to provide a realistic template.

III. Integration of green production and smart manufacturing

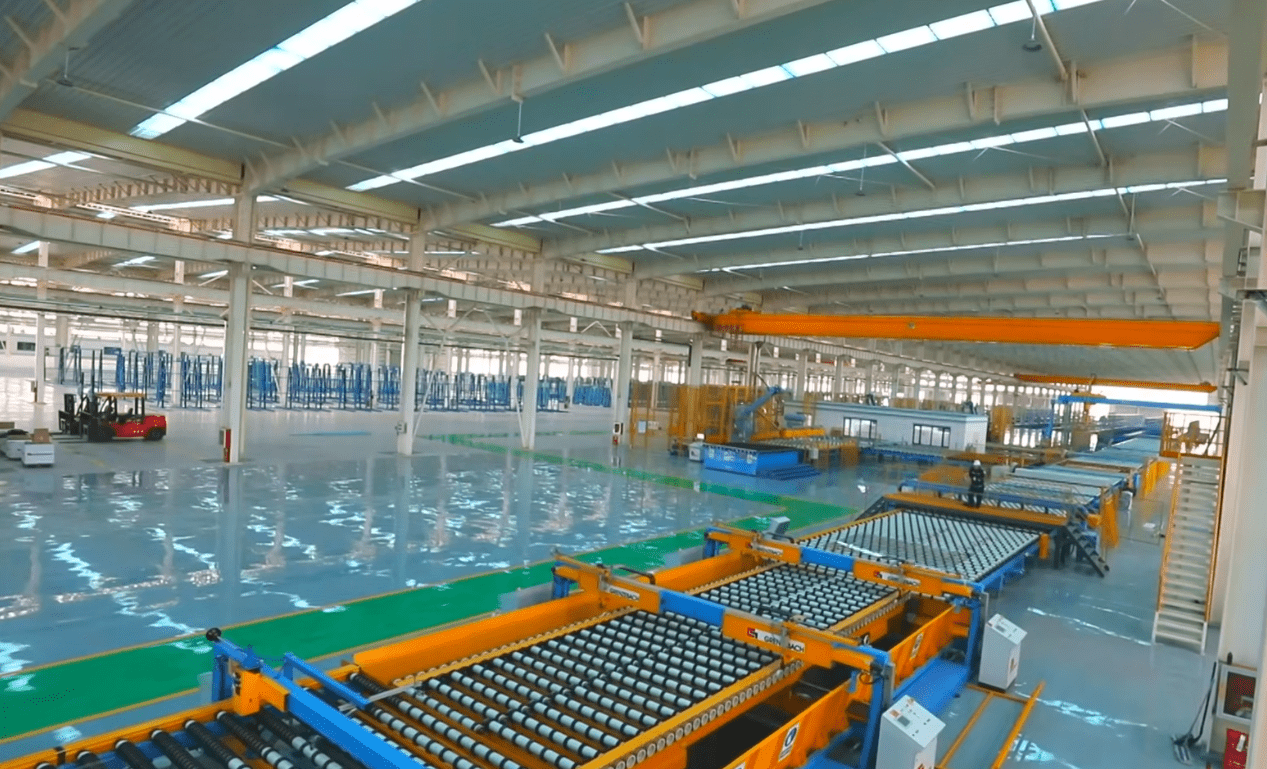

Aohua adopts ERP and MES system linkage management, combined with online quality monitoring (e.g. Isla system), which not only realizes automatic identification of product defects, but also real-time supervision and optimization of energy consumption and emission levels. In the cold-end production process, the equipment can be automatically scheduled and debugged according to orders, improving production flexibility and raw material utilization.

Intelligent system makes green management no longer only rely on manual control, but to form a traceable, adjustable, optimizable closed-loop management mode.

Fourth, the market advantages of green glass products

Aohua's main super-white float glass has the advantages of low lead, iron and impurities due to the selection of raw materials and composition control. After being coated and hollowed out, it can reduce building energy consumption by more than 30%. Under the green building certification system (such as LEED, Green Samsung), Aohua products have obvious competitive advantages.

In line with Aohua's "full life cycle" product service concept, the company intervenes in the project design stage to provide consulting and selection, green product selection data and supporting solutions to help customers realize the goal of energy-saving buildings from the source of design.

V. Future outlook: the twin-track drive of greening and internationalization

Green manufacturing is not only Aohua's compliance response, but also a brand strategy. As global carbon emission monitoring and trade barriers are getting tighter, green certification and carbon labeling will become the passport to the international market. Aohua plans to push its products into the North American and Southeast Asian architectural glass markets in the next three years, and to participate in international green building material certification, taking steps towards globalization.

Conclusion:

Aohua Glass has built a competitive system centered on product environmental friendliness, process cleanliness and management intelligence with green and intelligent two-wheel drive. Its pioneering advantage and institutionalized ability in the process of "carbon neutral" in the glass industry will become a model of green transformation in the industry.